There are many machines for all kinds of customer’s requirements in SEC.

Such as Electronic PCBA category and Inspection category to inspect the products quality.

SEC have many machines enough to produce high numbers of products, for sure.

SEC also have skillful employees and we also have preventive maintenance schedule for all M/C in order to get ready to use thyme under proper continuous quality control TPM.

SMT MACHINES

There are 14 lines. Such as Solder paste printer M/C, Chip Mounters, Reflow Oven, Automatic Optical Inspection, Solder Paste Inspection, X-Ray,

Laser Marking, Glue Dispenser, First Article Inspection etc.

AUTOMATIC INSERTION

There are 17 M/C (JV = 2M/C, Axial = 6 M/C, Radial = 9 M/C, Eyelet = 2 M/C)

MANUAL INSERTION AND WAVE SOLDERING M/C (Wave soldering M/C)

There are 8 production lines. Including all equipment, tooling, and the other manual processes.

Such as Hand Soldering, Jig Fixture, Part Preparation M/C, In Circuit Tester (ICT), Function Test (FCT),

Glue Dispensing, Potting and all production necessary tools.

MEASURING EQUIPMENTS FOR QUALITY INSPECTION

Such as TMM, CMM, Humidity Chamber, Vibration Test M/C, RoHs X-Ray Equipment and also others of inspection tooling,

Including Calibration Test Equipment.

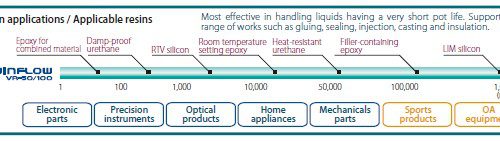

POTTING MACHINE VR-50 series (Available now)

Application for moisture and water prove product.

REFLOW - N2 is available now

Advantages/Benefits

The main advantages of using Nitrogen for Pb-Free Assembly in the reflow process v/s atmospheric air are as follows: